DTF Station

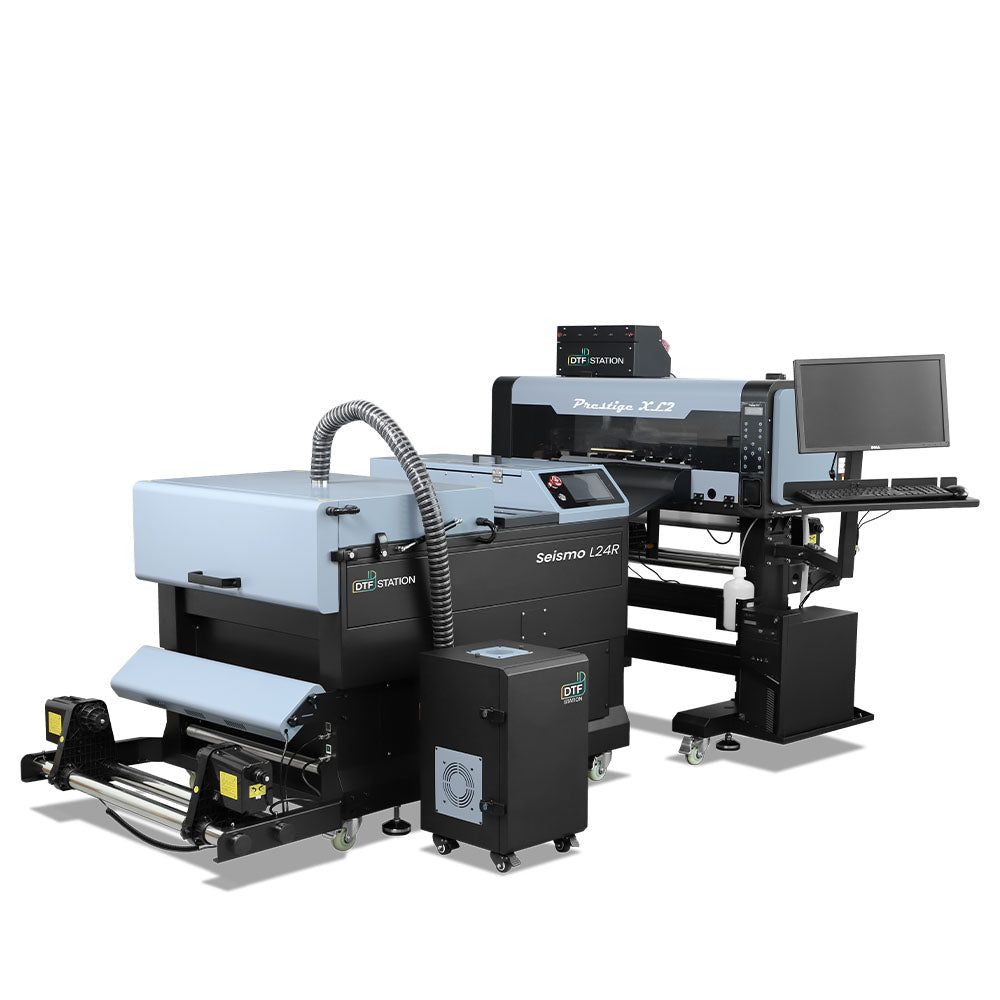

Prestige XL2 DTF Printer & Bundles

Prestige XL2 DTF Printer & Bundles

Couldn't load pickup availability

Find out how you can get 0% financing for 1 year on this machine!

The Prestige XL2 is your perfect high-end DTF printer option, with print speeds of up to 80 - 100 sq. ft./hour, premium print quality from 2 Epson i3200 printheads, and a suite of advanced features for easy use and maintenance.

Customize your XL2 purchase from the following options:

- Equipment Type: Miro 24, Seismo L24R, Seismo V24

All the bundles in this listing include the following products:

- Printer

- On-Site Training

- neoStampa RIP Software (Windows only)

- DTF Station Pilot

- Starter Supply Bundle

- 24" DTF Film Rolls (x2 each)

-

Color Prime DTF Ink (CMYK) - 1kg (x1 each)

- Color Prime DTF Ink (White) - 1kg (x2)

-

Color Prime DTF Hot Melt Powde - 1kg (x3)

- Color Prime DTF Cleaning Solution - 1kg

-

Isopropyl Alcohol 16oz

-

Lintless Wipe 4 x 4 30 Pack

- DTF Station 7" Cleaning Swabs 50 Pack

Access the speed and quality of true production DTF printing today with the Prestige XL2 DTF Printer. Plus, save when you bundle with one of DTF Station’s powder shaker & dryers for truly automatic DTF printing!

Get all the important parts to repair and maintain your printer in the L2/XL2 First Aid Kit from DTF Station.

Features:

- Two i3200 print heads

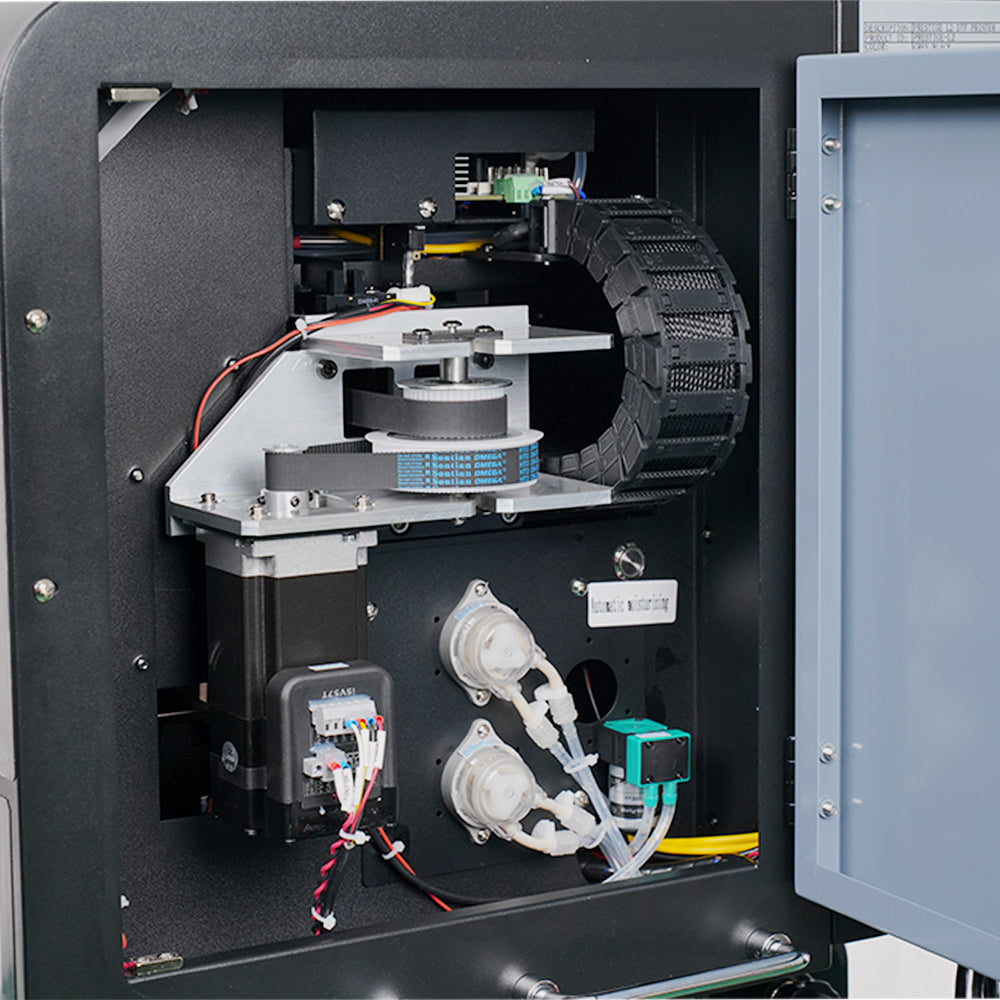

- White Ink Management System (WIMS): timed white ink stirring system to circulate and maintain white ink inside printer

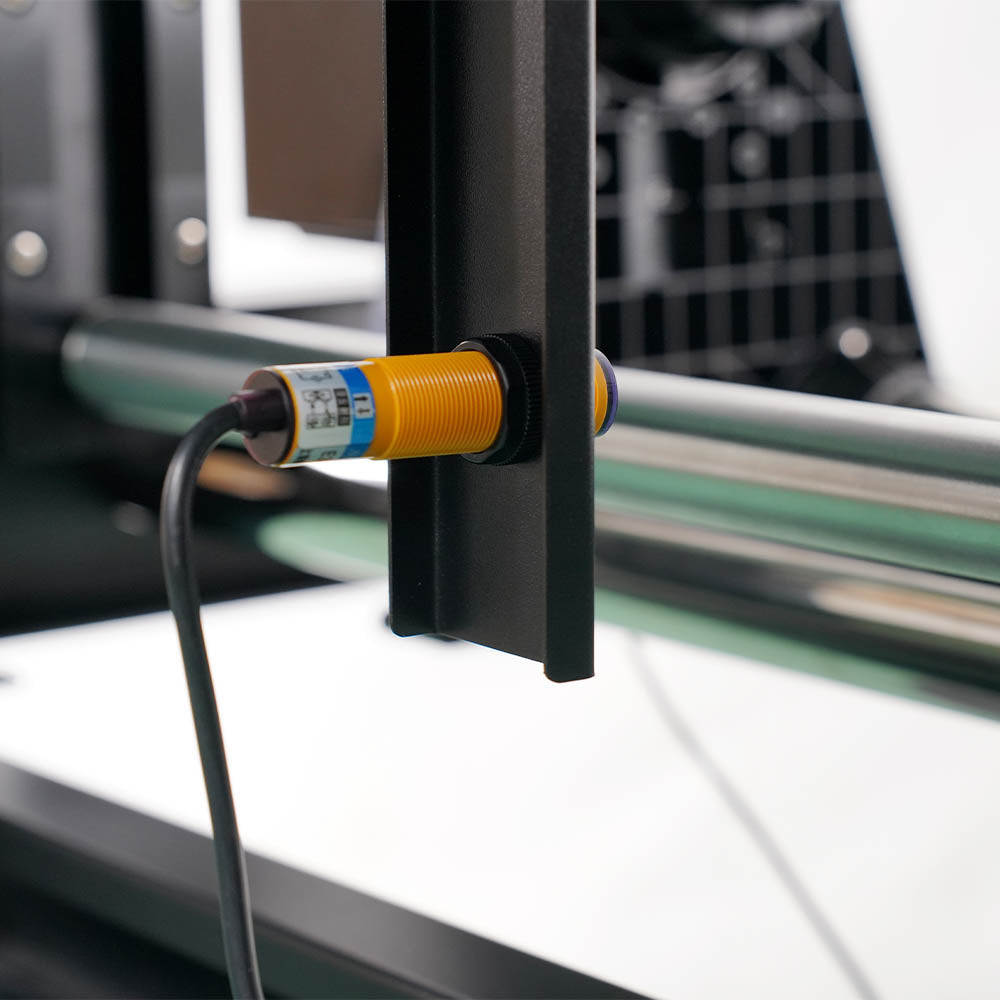

- Head Strike Sensor: helps prevent damage to printhead

- Passive Auto-Cleaning: when printer is left on, it will automatically maintain and clean printhead every 4 hours

- Active Auto-Cleaning: during set intervals (even during printing), printer can stop to clean printhead

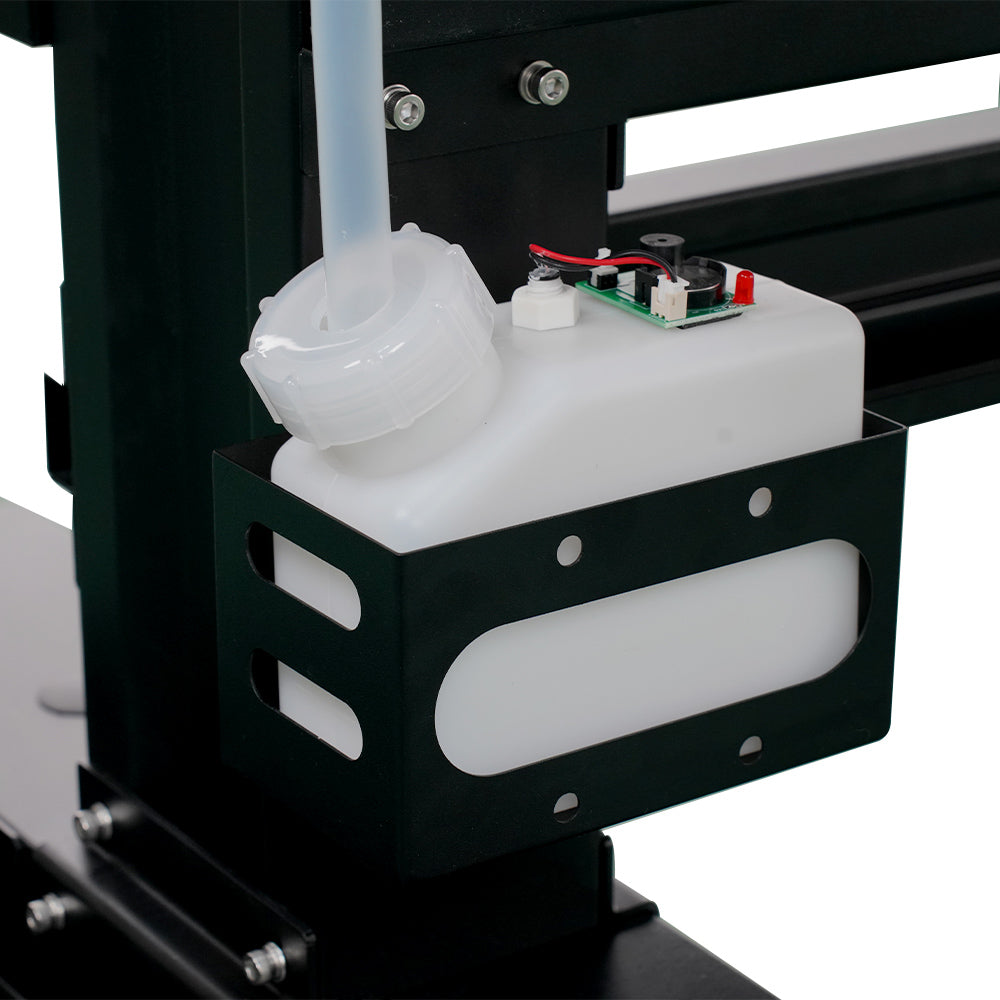

- Auto-Wet Capping: printhead sits inside cleaning solution while idle, helping to prevent clogging

-

Auto Ink Alert System: informs user when ink is running low

- Automatic Film Sensor: if film runs out/is not detected, stops printing

- Attachment Station: Perfect for add-ons, such as the Printflo Barcode Automation System

- Variety of adjustable settings including:

- Belt Speed

- Powder Shaking Power

- Cooling

- Suction

Benefits:

- Perfect for advanced productions: Get the best DTF prints at industrial speeds

- Advanced maintenance features: The suite of maintenance features on the XL2 ensure less downtime for non-stop production and a longer lifespan for your investment

- Easy access/repair: intuitive, labeled board design and connections for easy access and repair

What's included:

-

Conditional Warranty on up to 2 Printheads and Limited Warranty on Non-consumable Parts*

- *Use of non-DTF Station ink, film, powder, or other supplies will void warranty coverage. Details depend on training option selected. Terms & Conditions apply. Visit link for full details.

- neoStampa RIP Software (Windows only)

- DTF Station Pilot

Specifications:

| Print Head | Dual Epson I3200 Printheads (CMYK + WWWW) |

| Mainboard | Hoson |

| Interface | TCP |

| Software | neoStampa RIP Software (Windows only) and DTF Station Pilot |

| Max. Film Width | 24" (61 cm) |

| Max. Print Width | 23.62" (60 cm) |

| Printing Speed | 80-100 sq. ft./hour |

| Operation Environment | Temperature:15℃-30℃ (60 °F-86°F), Humidity:35%RH-65%RH |

| Power Requirements | 800W, 110V, 9A |

| Product Weight | 339 lb |

| Packaging Weight | 383 lb |

| Product Dimensions (WxDxH) |

52.75" x 26" x 55" |

| Packaging Dimensions (WxDxH) |

58" x 43.25" x 28.5" |

Applicable Industries

- Garments

- Tote Bags

- Caps

- And more!

- Fabrics:

- Cotton

- Polyester

- PU

- And more!

Compatible With

- Color Prime DTF Supplies